Visual Vocabulary

Many terms used to describe glass deterioration are not well defined nor consistently applied. In addition, terms commonly used for cultural heritage are often not widely understood or even known to those outside the field. The visual vocabulary below presents terms that describe visual symptoms of glass deterioration in objective and measurable ways. These terms are useful for documentation as well as a useful tool to aid assessment of deterioration of Laurent’s glass flutes and photographic glass. The vocabulary and accompanying pictorial examples are grouped into three broad categories: little to no deterioration, intermediate deterioration, and advanced deterioration. You can help us further our research by taking this short survey called the Visual Validation Tool. The Visual Validation Tool (VVT) is an A-B survey comparing glass surfaces to find the so-called ground truth for our image and texture analyses of glass surface deterioration.

glass deterioration

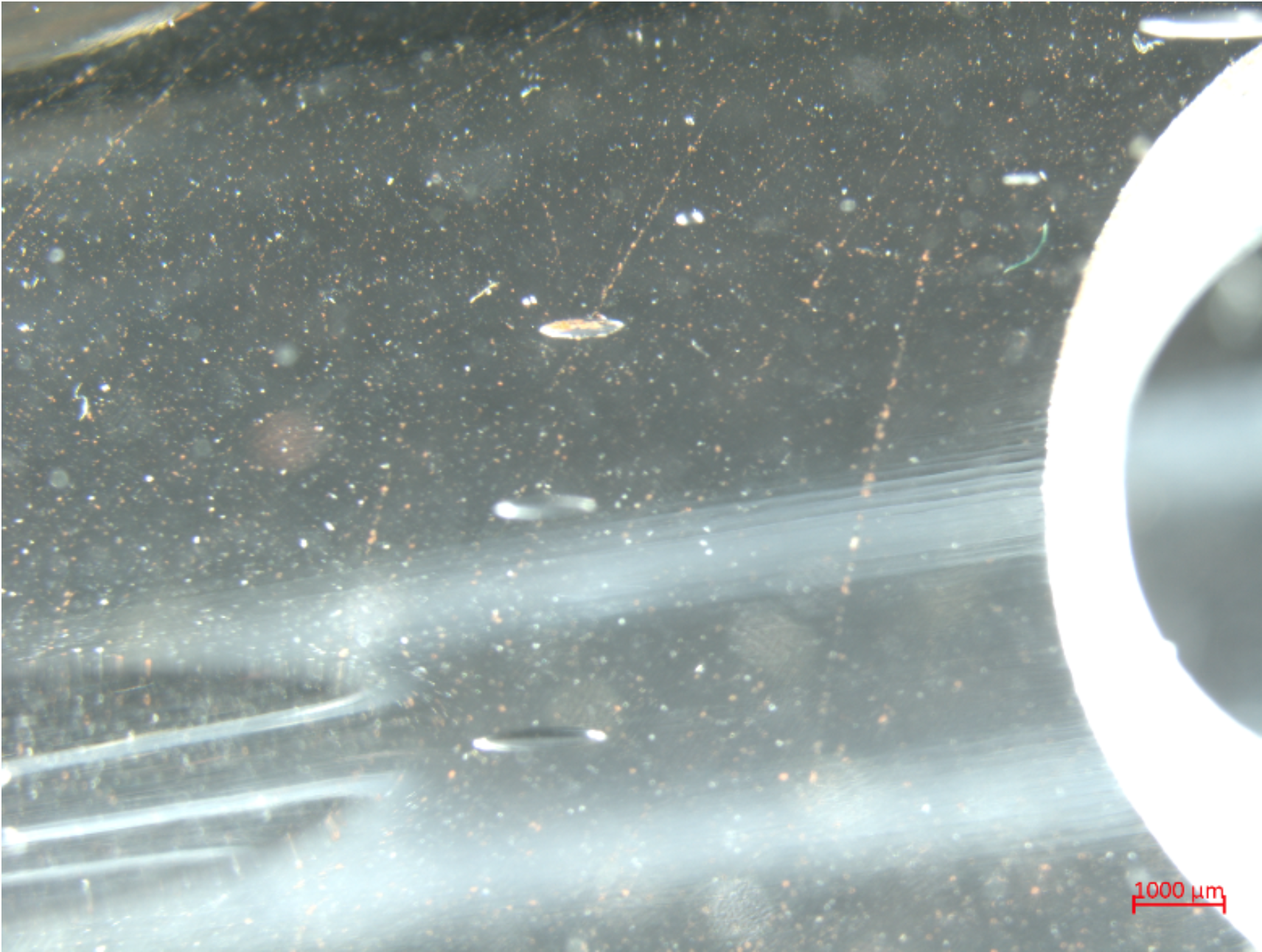

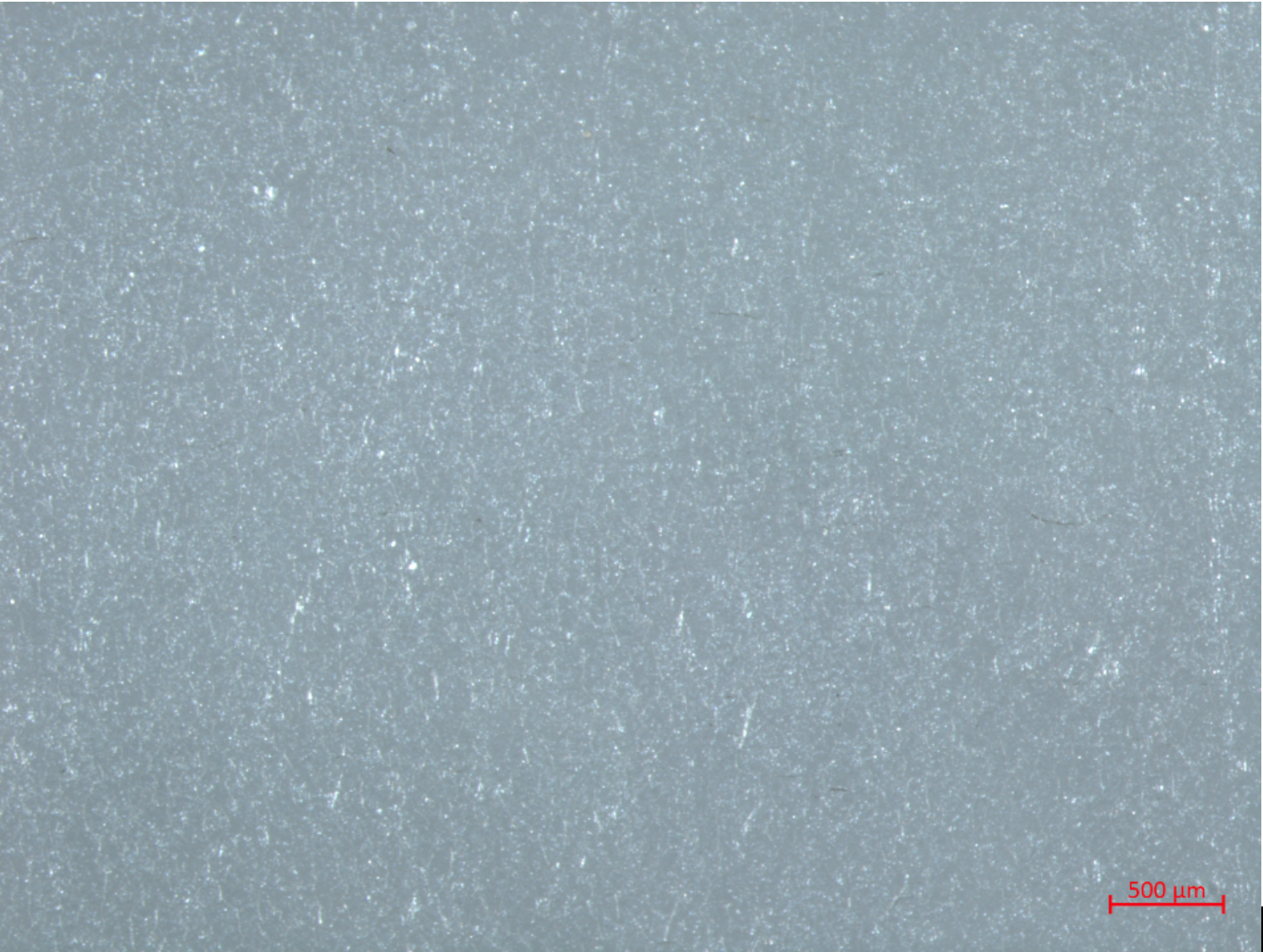

Little to no visible deterioration

Little to no visible deterioration designates that there are few if any visible deterioration markers at magnifications ranging from the naked eye to higher magnifications (>25x).

Intermediate deterioration

Intermediate deterioration designates the formation of microscopic features on the glass surface that are not visible to the naked eye, but detectable with low (< 10x) to high (>25x) magnifications.

Advanced Deterioration

Advanced deterioration is characterized by phenomena that are dense enough across the surface region of the glass to become visible to the naked eye through light scattering, which produces different degrees of opacity. Note that not all glass surfaces are produced with a high polish, making opacity difficult to determine in many cases.

terminology

opacity

Opacity in glass arises from features that cause light scattering. In cultural heritage glass, opacity may arise from either intentional manufacture or deterioration. Intentional opacity, producing a “frosted” or satin glass appearance, is made by rough polishing or acid etching of the glass. As the by-product of deterioration, opacity arises from light scattering from cracks and/or surface particulates. Unintentional opacity can occur unevenly over the surface of an object. The Laurent flutes, for example, exhibit both intentional opacity from rough polishing, as well as opacity from cracking. Opacity caused by surface accretions has not been observed in the Laurent flutes. Note that the presence of both forms of opacity renders assessment of deterioration difficult, especially when cracking occurs in rough-polished and frosted glass areas.

cracking

Surface cracking occurs on a microscopic scale and can range from fine to coarse, depending on whether the cracks start to separate and become easily visible from scattering light at their edges and within the cracks. Cracks themselves form in different shapes, most likely related to residual stresses in the glass, and may join up as cracking develops into network patterns. These shapes and patterns are described by cracks that are near-perpendicular to the surface, extending into the alteration layer. Cracks can also form under the alteration layer, near-parallel to the surface, leading to delamination and spalling.

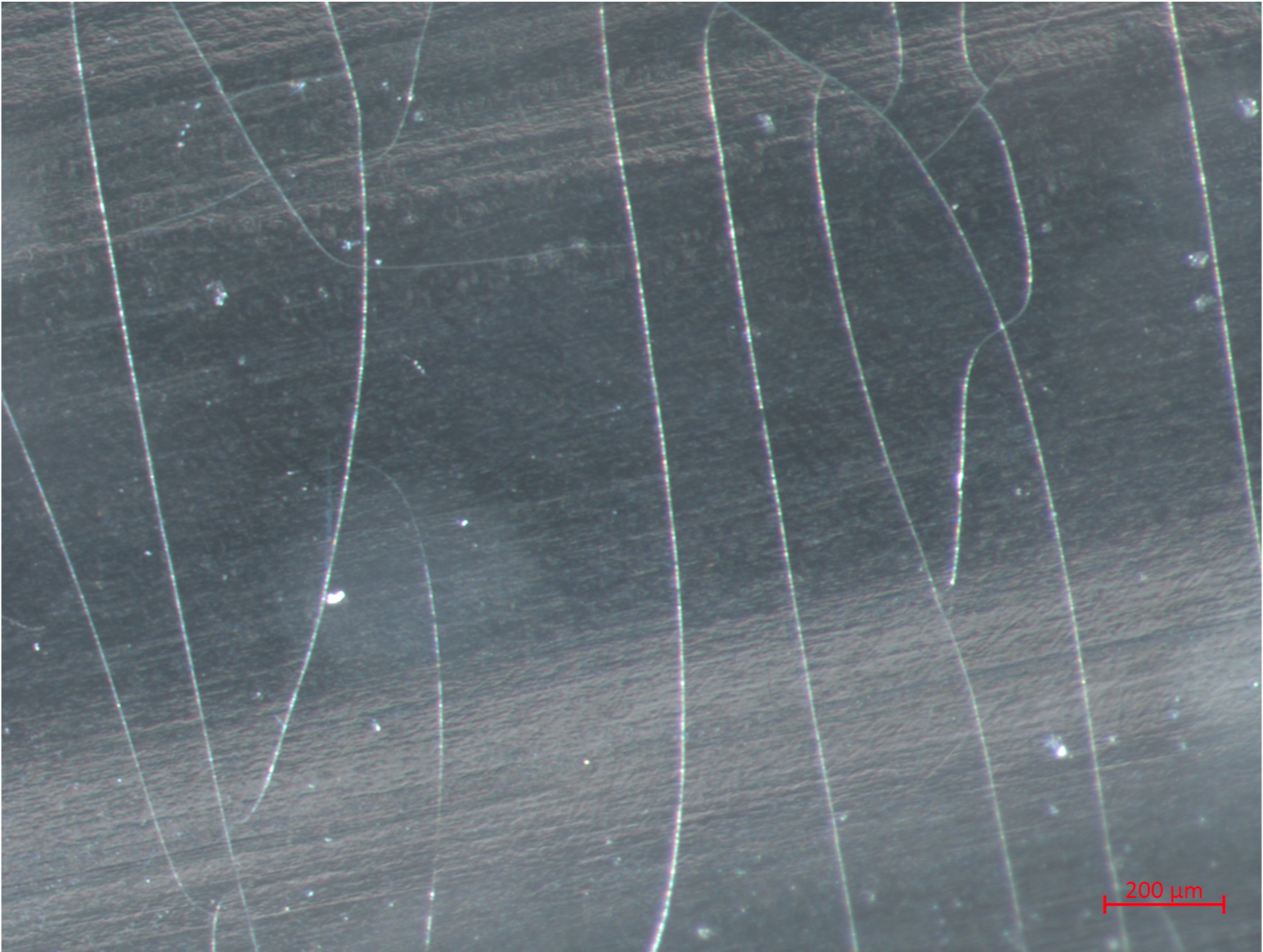

Left: Laurent flute DCM 475, exterior surface, head joint above the cork in fluting, polished surface with fine arced microcracking, some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~25x magnification.

Right: Laurent flute DCM 475, exterior surface, short upper body joint, polished surface with fine arced microcracking and some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~66x magnification.

Fine microcracking

Fine microcracking can be observed at medium to high magnifications with the aid of raking light that catches crack edges that have no perceptible separation.

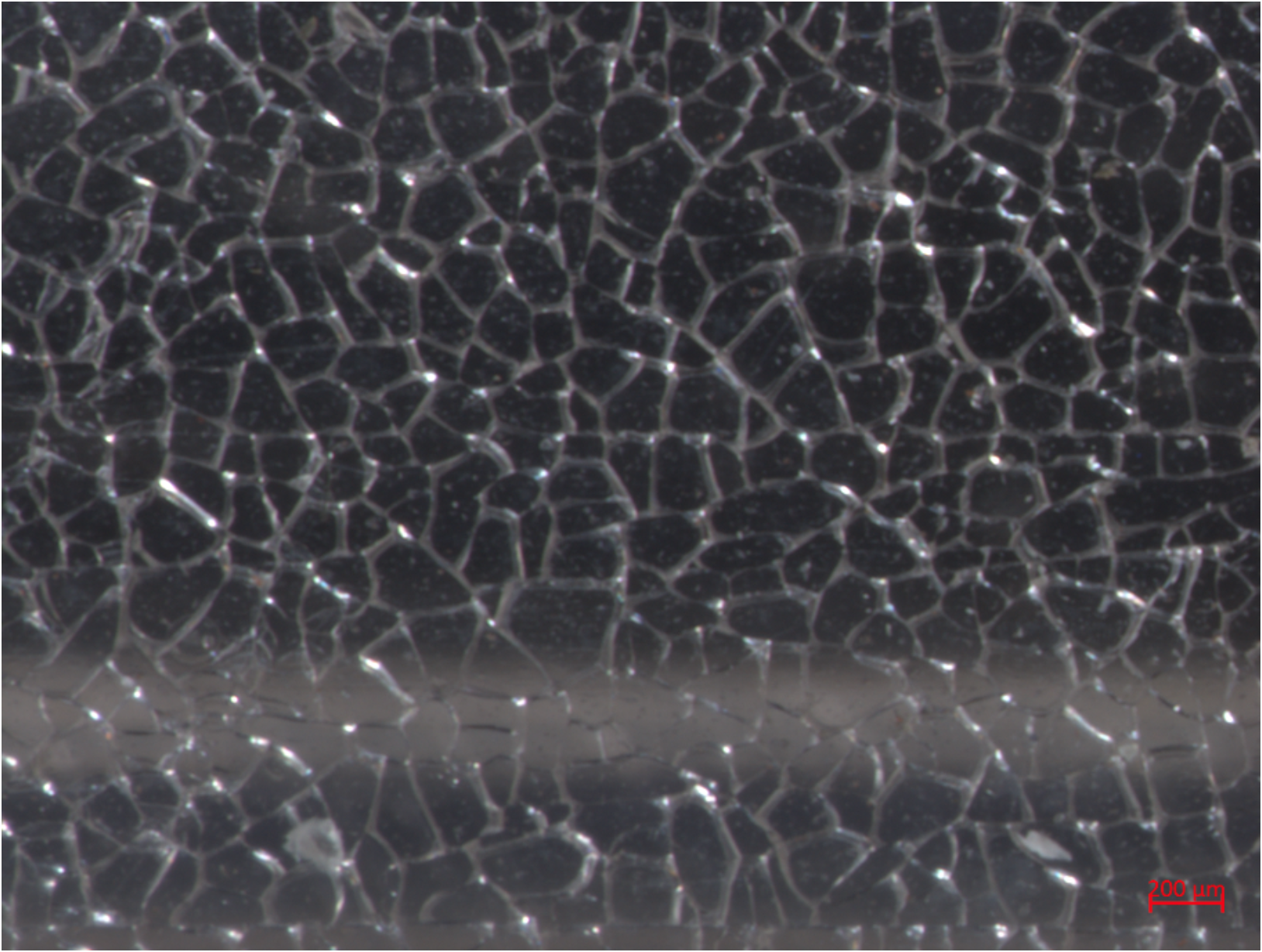

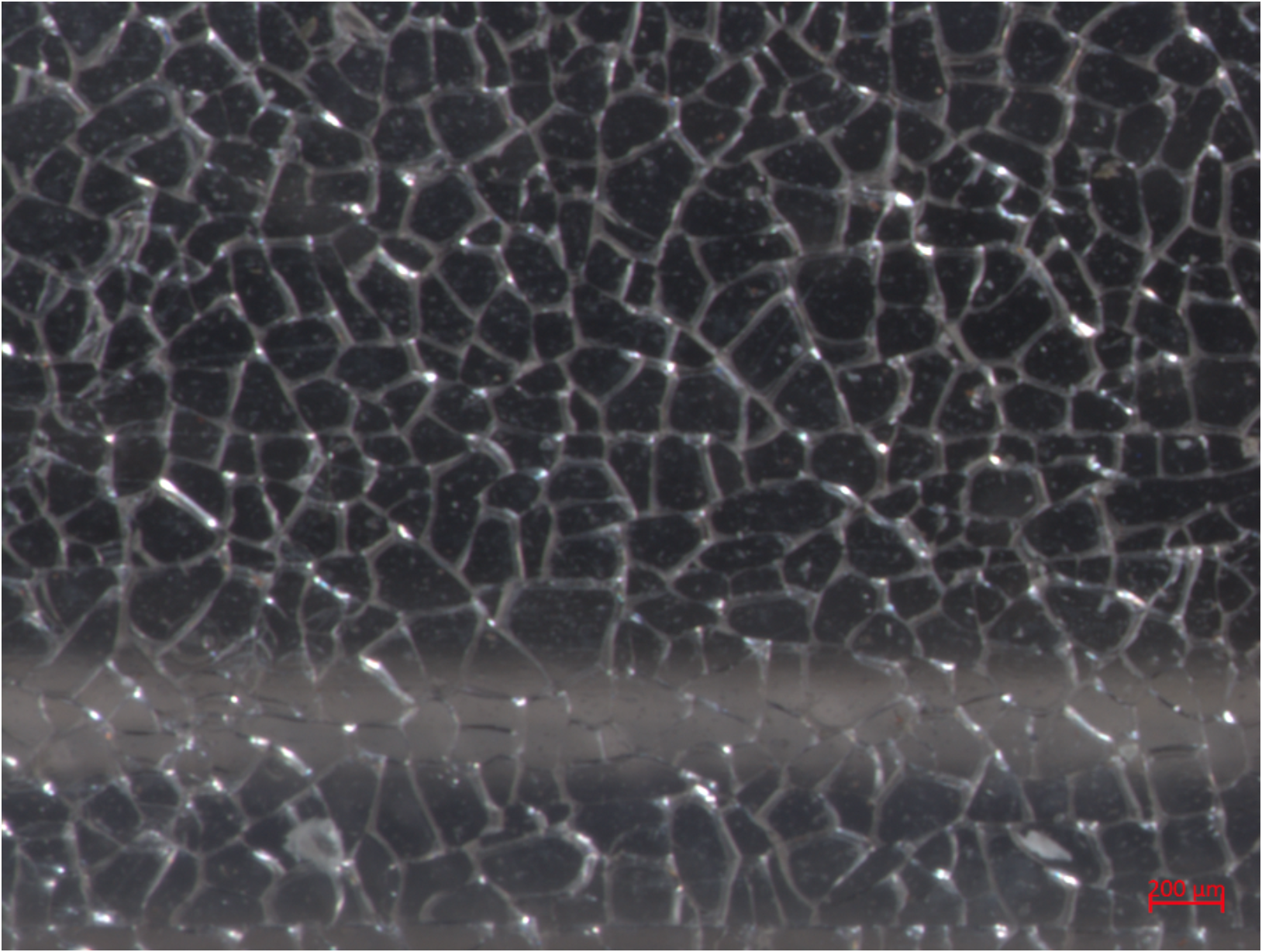

Left: Laurent flute DCM 475 opacity via unintentional degradation, interior surface, head joint below embouchure, rough polished surface with polygonal network microcracking and some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~40x magnification.

Right: Model glass composition F75, artificially aged seven days at 90°C and 90% relative humidity with coarse, t-joint and polygonal network cracking and spalling imaged with an iPhone camera with a clip-on 10x objective lens

Coarse microcracking

Coarse microcracking can be observed at low to high magnifications with or without the aid of raking light that catches crack edges; in this case separation between cracks catches light and has a width that is potentially measurable.

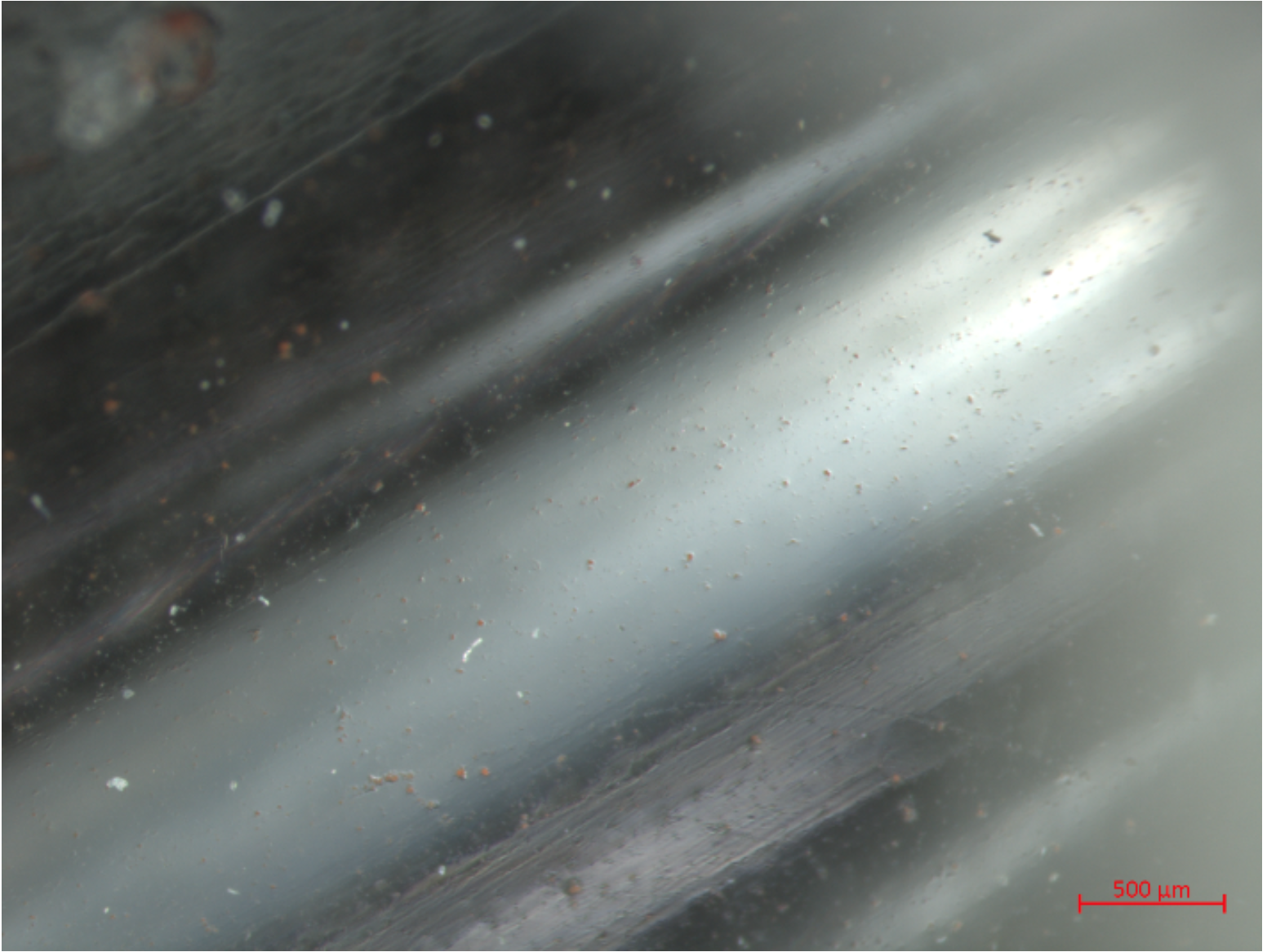

Laurent flute DCM 475, exterior surface, head joint above the cork in fluting, polished surface with fine parallel linear cracking, some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~25x magnification. Also note the presence of some arced linear cracks.

parallel linear cracking

Parallel linear cracking can be observed at low to high magnifications with or without the aid of raking light; the cracks appear as lines that are roughly straight and usually arranged in series of parallel cracks.

Left: Laurent flute DCM 475, exterior surface, short upper body joint, polished surface with fine arced microcracking and some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~66x magnification. Also note the presence of some parallel cracks

Right: Laurent Flute DCM 1680, lower body joint exterior surface imaged with a Zeiss STEMI stereomicroscope at ~12x magnification. Note other polygonal cracking patterns on the surface.

arced linear cracking

Arced linear cracking can be observed at low to high magnifications with or without the aid of raking light; the cracks appear as lines that arc or bend gradually and may be arranged in series. This type of cracking is often seen in the ground depressions that describe a fluting design, and may be related from residual stresses caused by this post-manufacture procedure.

Left: Laurent flute DCM 475, interior surface, long upper body joint through middle tone hole, rough polished surface with fine arced microcracking and some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~50x magnification.

Right: Model glass composition F5 aged seven days at 90 degrees Celsius and 90% relative humidity with t-junction cracking imaged with a Zeiss Axio stereomicroscope in bright field imaging mode at ~500x magnification. Note also the polygonal cracking patterns, surface accretions and iridescence from minor delamination.

t-junction Cracking

T-junctions are cracking patterns where two cracks meet at a nearly ninety degree angle. T-junctions are often seen in the initial and intermediate stages of surface crack development. T-junctions are hard to detect with the naked eye, since they are often associated with fine individual cracks, and are often visible at low magnifications (~10x).

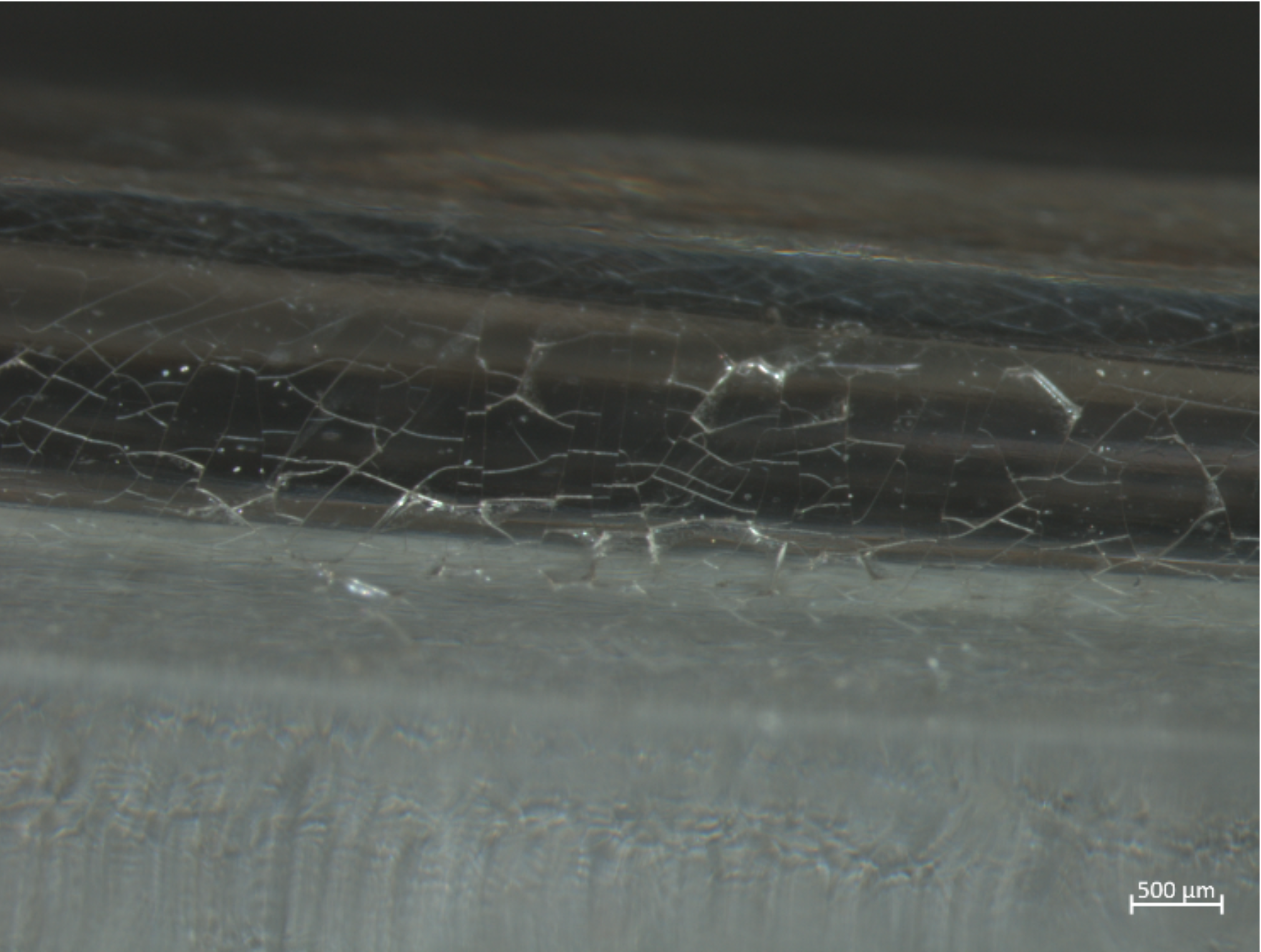

Left: Laurent flute DCM 475, interior surface, head joint through embouchure, rough polished surface with coarse polygonal cracking imaged with a Zeiss STEMI microscope at ~25x magnification. Scale bar: 200μm.

Right: Laurent flute DCM 475 opacity via unintentional degradation, interior surface, head joint below embouchure, rough polished surface with polygonal network microcracking and some t-joint and angled cracking imaged with a Zeiss STEMI microscope at ~40x magnification. Scale bar: 400μm.

polygonal network cracking

In advanced microcracking, linear cracks may appear to join up, causing denser and denser networks of cracks. Advanced network cracking often appears in somewhat regular, course polygonal cracking patterns that can be described by angle, surface area, diameter, number of sides and side length. Due to light scattering, these patterns can often be seen by the naked eye as opacity, but are best described with medium magnification (10-25x).

Left: Spalling on Laurent Flute DCM 717 at lower body joint imaged with Zeiss STEMI stereomicroscope at 12x magnification. Scale bar: 1 mm.

Right: Spalling on Laurent Flute DCM 717 lower body joint imaged with Zeiss STEMI stereomicroscope at 66x magnification. Scale bar: 200 μm.

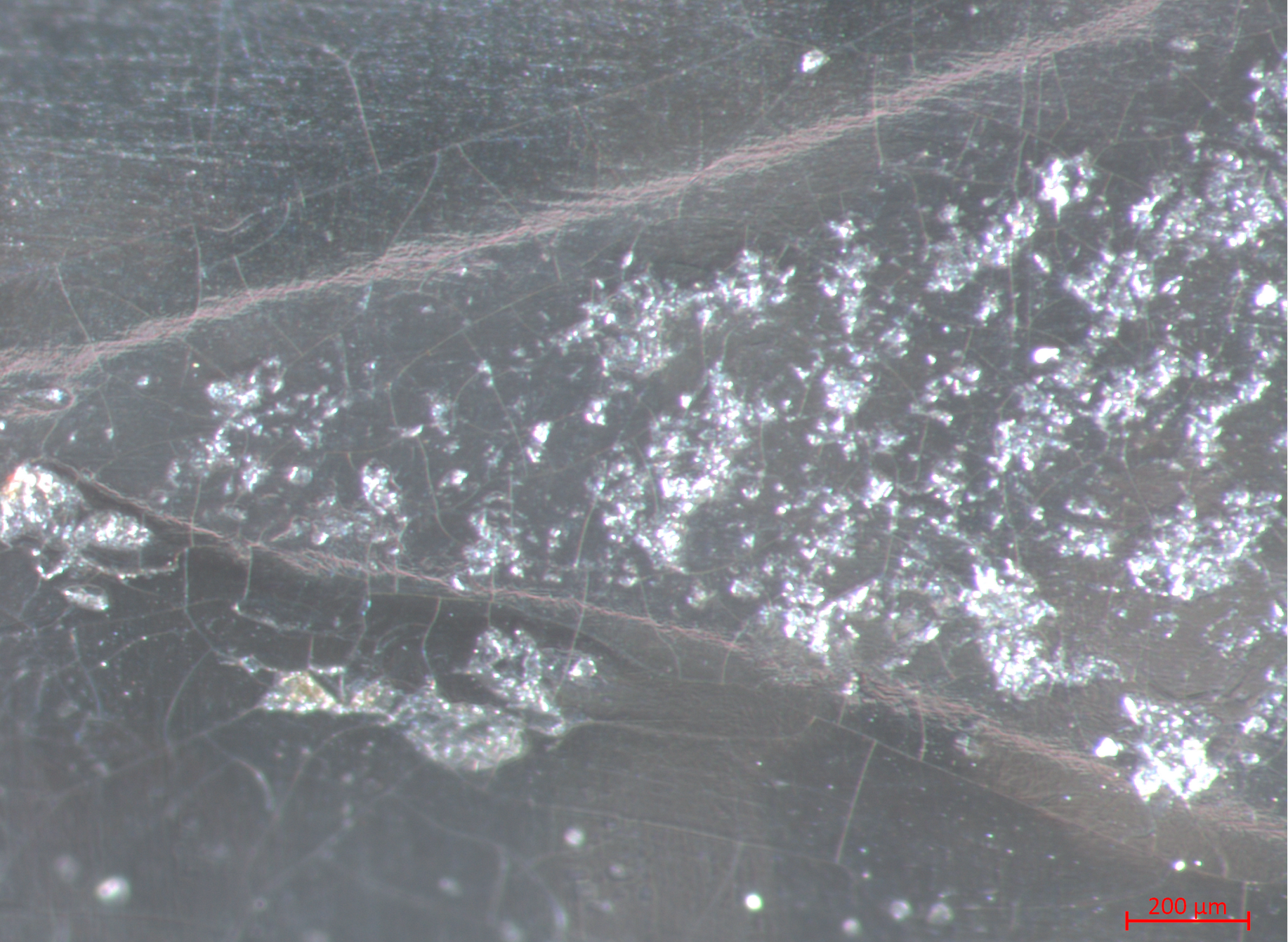

delamination and material loss

Delamination occurs when the altered glass surface layer wholly or partly separates from the bulk glass underneath.

The delaminated layer can be of different thicknesses, appearing as flaking or spalling of chunks of glass between network cracks. Depending on the size of losses, this type of advanced deterioration can normally be seen at low-high magnification. Separated fragments of glass may be found around the object.

Losses are often seen at medium-high magnification at the interstices of joined cracks. At low magnification or the naked eye, these can appear as dirt, since shadowing in the losses make them appear dark. Delamination and spalling in severe cases can be seen with the naked eye, however, to gauge the extent of delamination and spalling, a low to medium magnification (<25x) is recommended.

Surface Accretions

Any substance that accumulates on the glass surface can be called an accretion. Alkali silicate glasses that are not sufficiently stable in any given environment are particularly susceptible to the formation of surface accretions, although this is not a necessary symptom of deterioration. In addition, surface accretions of foreign origin may be present. Dirt, debris, and polishing residues are often observed at low magnifications, and can easily be confused with precipitated alkali salts, for example. Identification of polishing residues and dirt on the Laurent flutes has been made by X-ray diffraction and Raman spectroscopy.

Surface accretions include both solid particulates and liquid droplets. Liquid droplets with solid centers are also possible. On alkali silicate glass in particular, these accretions may be by-products of alkali leaching through the hydrated alteration layer. After leaching, alkali ions can react other substances, including air, and form a by-products that remain liquid, partially liquid, or precipitate as crystalline salts. Such surface accretions occur can appear in concentrated, isolated areas or spread fairly evenly across larger areas. The required magnification to detect precipitates and liquid droplets depends on both their density across the surface and feature size. Among 19th century glass cultural heritage, photographic glass often exhibits these features at low to medium magnification, with droplet size ranging from the nano- to micrometer scale.

other phenomena

pitting

Pitting appears as tiny groups of rounded pits. This can occur from contact with acids or extended contact with liquid of any kind. It is not clear whether pitting is necessarily associated with deterioration of the bulk glass or occurs as isolated cleaning events.

loss of adhesion and emulsion cracking

Loss of adhesion and emulsion cracking can occur on coated glass, such as photographic image glass, from invisible surface accretions underneath the varnish or emulsion.

biological growth

Biological growth is often seen on glass surfaces exposed to high humidity, such as glass used in photographic enclosures. Although the growth itself may only be attached to the glass, biological activity is usually a sign that the glass has been exposed to humidity and thus potentially undergoing deterioration.

discoloration

Discoloration of clear glass may occur from oxidation of manganese oxide (MnO2) that was added to the glass for purposes of decoloration. Upon further oxidation over time to MnO4, a purplish-brown tint may appear. Discoloration also occurs from accumulation of dirt, oxidation of surface oils, or discoloration of a varnish.